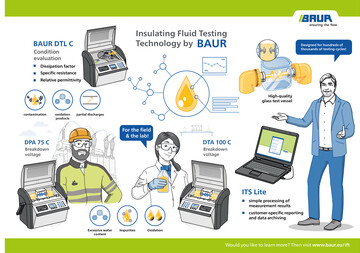

DPA 75 C

Oil breakdown voltage tester

Insulating oil testing with the BAUR DPA 75 C

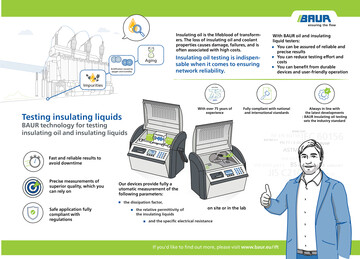

The BAUR DPA 75 C oil tester developed especially for mobile use in the field is one of its kind in the market due to its functionality and excellent user benefits in comparison to the costs. The BAUR DPA 75 C delivers clear and reliable measurement results.

- Compact and robust device for portable use onsite

- Test voltages from 0 to 75 kVrms

- Repeatable breakdown measurements in mineral, silicone and plant oils

- Reliable measurement results due to its short switch-off time (< 10 μs)

In order to obtain meaningful results from insulating oil testing, oil samples must be properly taken by suitably trained personnel. Here are a few tips to help you take samples without any issues:

Product information

Literature

Supplementary:

DTL C

Oil tan delta and resistivity tester

Report Manager

External USB interface

for BAUR oil testers

BAUR ITS Lite software

Measurement data management

for oil testers

Other interesting products:

DTA 100 C

Oil breakdown voltage tester