Cable fault location process

Step-by-step guide to locating cable faults with the cable fault location process

The objective of fault location is to locate a cable fault as quickly and precisely as possible so as to provide the ideal basis for fast repair and reconnection. Our devices have a wide spectrum of measurement methods and thus provide you with maximum support in locating the fault.

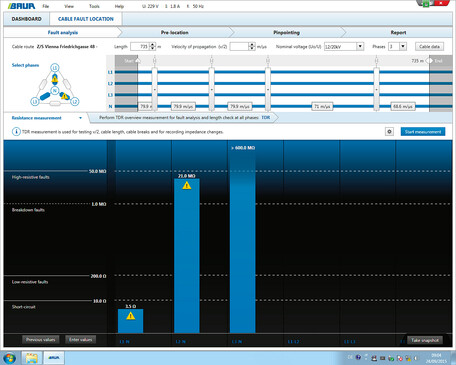

Fault analysis

Measurement methods for fault analysis in cable fault location:

Insulation resistance measurement

to determine the faulty phase and the type of fault.

Voltage test

to test the dielectric strength of the cable insulation.

Cable sheath testing

to detect damage to the outer cable insulation (cable sheath faults).

Pre-location

Measurement methods for cable fault pre-location:

Conditioning SIM/MIM

Difficult to locate or wet faults are first conditioned with surge voltage before a SIM/MIM measurement is carried out.

DC-ICM

Impulse current method used in DC mode for locating chargeable breakdown faults for which the cable capacitance is used in conjunction with a surge voltage generator.

DC-SIM/MIM

Secondary/multiple impulse method in DC mode for pin-pointing intermittent faults. DC voltage is applied to the cable until a breakdown occurs. The cable capacitance is used to increase the available surge energy.

Measurement mode with envelope curve display

In this process, even small, intermittent changes to impedance can be made visible by means of an envelope curve and saved automatically.

Fault conditioning/burning

High-resistive cable faults are handled with high performance high voltage burn down transformers. The ensuing fault becomes low resistive and therefore can be easily measured according to the TDR method. This application is used for the conventional paper-lead-sheath cables.

TDR

Time domain reflectometry for locating low-resistive faults and cable breaks, and for determining the cable length.

Multiple impulse method (SIM/MIM)

The secondary/multiple impulse method is the most well-established and precise cable fault pre-location method. High-resistive faults and breakdown faults are triggered by a single HV pulse, and the fault distance is measured very precisely several times via the TDR technology and automatically evaluated.

Decay method

Voltage-coupled decay method for locating faults with high breakdown voltage. The oscillating voltage reflection waves are evaluated automatically to determine the fault distance.

Impulse current method (ICM)

Impulse current method for locating high-resistive faults and breakdown faults. The fault distance is determined by evaluating the impulse current diagrams. Particularly suitable for use on long cables.

Tracing and pin-pointing

In the case of newly installed cables, detailed data is often available, for example in a Geographical Information System (GIS). If this is not the case, tracing must be performed with suitable devices. There are two methods available for this:

Measurement methods for tracing and cable fault pin-pointing:

Acoustic pin-pointing

is the most common method used to determine the precise location of high-resistive faults and breakdown faults. High-voltage pulses create electromagnetic pulses on the way to the fault location and generate a breakdown with an audible bang.

Step voltage method

to determine the precise location of cable sheath faults. A voltage gradient is generated at the fault which can be located using earth spikes and a receiver.

Tracing

to precisely determine the cable route. Precise cable tracing is essential, particularly with unknown or imprecise cable routes, and saves both time and money.

Twist method or minimum distortion method

used when pin-pointing short-circuits depending on the cable type. In this process, the disturbance in the otherwise homogeneous magnetic field that is caused by the fault is measured and located precisely.

Cable identification

Measurement methods for cable fault identification:

Cable fault identification

is used to identify single- and multi-core cables in a cable loom. The measurement engineer is provided with precise information as to which cable needs to be tested and, where necessary, cut.

Detailed information on cable fault location