"We take the complexity out of cable diagnostics"

Interview with Tobias Neier, Head of the BAUR Diagnostics Centre of Excellence

With cable diagnostics, the condition of underground cable systems can be assessed, targeted planning of repairs and investment undertaken, and unplanned outages often avoided. This unlocks potential savings and increases the security of network supply. While cable testing only returns a "passed" or "failed" result, cable diagnostics provides much more detailed information. Using this information, it is possible to determine how long cables can still be used cost-effectively or where weak points exist. As Tobias Neier, Head of the BAUR Diagnostics Centre of Excellence, explains, cable diagnostics is a bit like a health check at the doctor's. And, as is the case with a doctor, cable diagnostics also requires knowledge of how to use the equipment, experience in evaluating the results, and the ability to interpret each measurement individually. Only then is it possible to assess the state of health and to take any measures necessary to improve it. In the interview, Mr Neier explains how the Diagnostics Centre of Excellence helps operators to implement cable diagnostics and to further develop their knowledge and experience.

Mr Neier, you compare analysing the cable condition with a check-up at the doctor's – why?

Just as every patient is different and requires an individual interpretation of laboratory and measurement results, so too are cable systems. To assess their condition, experience is needed when evaluating the results. This is a daunting prospect for many because there are no generally valid limit values. But those who learn to use cable diagnostics are able to obtain valuable information about the "state of health" of their distribution network, increase the security of supply, and can typically reduce costs considerably.

What are the actual economic benefits of cable diagnostics?

Knowing the condition of your cables allows you to estimate their remaining life time, enabling better planning of investment in replacements. Often the remaining service life is extended by many years. Or you can identify gradually developing weak points and avoid failures as a result, combined with a more targeted and cost-effective approach to repairs. And for new cable routes or repaired sections, cable diagnostics can show whether the route is OK and the cable accessories have been properly mounted. This also helps to prevent faults from creeping in.

But cable diagnostics takes time – is it really worth the effort?

Definitely, especially for older distribution networks. Anyone who just replaces their 40- or 50-year-old XLPE cables after their intended service life has been reached is simply throwing good money away. That's because many cables are in much better condition than their age would suggest. The advantage of diagnostics here is that it provides meaningful information about the condition of the cable and, unlike cable testing, it is non-destructive. So even if the measured cable has reached the end of its service life, the measurement will not "test it to destruction". Rather, the diagnostics would reveal weak points, enabling you to plan repairs or replacement.

Is the purpose of diagnostics to reveal such weak points or to prove that the cable is in good condition?

Both. However, from an economic perspective, the added outcome that cables can remain in use for longer based on their condition is more important in practice, as this results in the savings already mentioned.

Why is cable diagnostics not used by all distribution network operators?

There are probably two reasons for this. Firstly, they have to purchase the appropriate technology and justify both the investment and the time spent on diagnostics to management. Secondly, there is often uncertainty as to how the diagnostics should be best carried out and the results evaluated in order to achieve the desired economic benefits.

…so it's a question of investing time and gaining experience…

Exactly. In terms of time, BAUR VLF cable diagnostics now offers many options for carrying out measurements quickly and integrating them easily into the work processes of the field service team. For example, we now offer rapid online partial discharge measurement, which allows you to preselect the cable routes to be diagnosed. In addition, offline measurements to determine partial discharges and the dissipation factor can be carried out in parallel and even combined with cable testing. This significantly reduces the time involved.

They sound like simple measurements and measurement procedures. Why do you also offer consulting services in this area?

Because – just like medical equipment used by doctors – handling the devices requires training, and because we show operators that they can not only perform standard procedures, but also implement their own diagnostics philosophy using our devices. This requires more training, but can significantly increase the benefits for the company. Ultimately, network operators can implement their own individual diagnostics strategy.

This means company-specific, similar measurement cycles on all relevant devices, which can also be performed by less experienced operators. This ensures consistent, comparable results that enable a high degree of reliability when it comes to assessing the cable condition, especially after several years of diagnostics. And just as a doctor gets to know their patients better over time, so asset managers benefit from the "patient files" of the cables. They can see trends and draw appropriate conclusions regarding maintenance.

But device training is not the only thing the Centre of Excellence offers. What other services does your team provide?

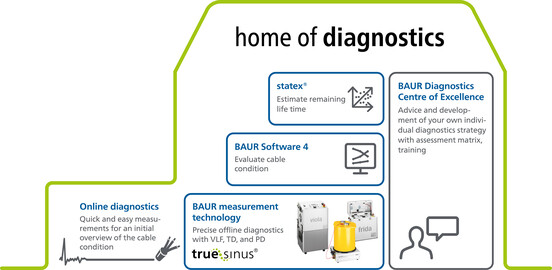

Our services range from providing advice before making a purchase, training courses for devices and software, creating a diagnostics strategy and assessment logic right through to optimal implementation of the statex® analysis software. At BAUR, we talk about being the "home of diagnostics" and we want operators to feel at home with diagnostics in every area – measurement, evaluation, and assessment.

You just mentioned pre-sales advice. How does that work?

First of all, we work with the customer to determine what is important to them. To do this, a number of questions need to be answered: Is reliability the main concern, is it maintenance costs, or is the network in such a state that major investment in replacements is likely in the near future? What is the existing network topology? For example, an intermeshed urban network places completely different demands on the diagnostics strategy than would a rural network with many spur lines or the distribution network of an industrial park. And, of course, the type of cables used – whether paper-insulated, first generation or more recent XLPE, PE cables, etc. – is important. Based on these factors, we can come up with recommendations for the correct procedure for cable diagnostics and the appropriate technology and evaluation logic.

You mentioned online diagnostics earlier. What role does it play in making diagnostics more efficient, for example, with the help of the VDS PD coupler?

Online diagnostics plays a major role here, because it is quick and easy to perform. We only recently launched the VDS PD coupler onto the market. It is an accessory for our liona measuring device that makes it possible to detect partial discharges (PD) on cable routes without taking them out of operation. The coupling unit is simply connected to the VDS sockets of the switchgear. The measurement therefore only takes a few minutes and offline partial discharge measurement is only necessary if the online measurement indicates a critical condition. So, all in all, operators have to spend much less time on PD measurements, as experience has shown that the majority of measured routes are in good condition.

What other options are there for carrying out cable diagnostics in a time-saving way?

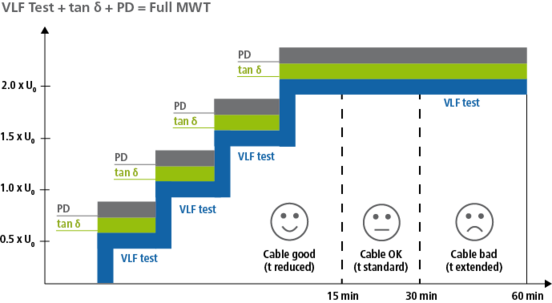

The test voltage is increased gradually. If the measurement results indicate a healthy cable, the procedure can be shortened. If, on the other hand, the cable appears to be severely aged or damaged, an extended measuring time provides certainty. It is therefore only necessary to measure and test for as long as is appropriate for the cable condition.

The advantage here is that cable testing is not carried out if the diagnostics already indicate a damaged cable. This prevents cables from failing as a result of testing.

The evaluation of the measurement results also saves time. Based on criteria that can be defined by the operator, the report initially differentiates between good cables, cables that require observation, and severely service-aged cables. If urgent action is required, the measurement engineer on site can see this immediately on the measuring device or at the beginning of the report. The measurement reports become more specific as they progress. The reports can of course be easily exported and processed further in asset management, for example to make comparisons or determine trends.

So dissipation factor measurement and partial discharge measurement are both relevant. Why is dissipation factor measurement important for condition evaluation?

To explain this, let's use the doctor analogy again. If you only took a partial discharge measurement, it would be like doing a check-up based simply on the patient's pulse and blood pressure. So, for example, you wouldn't be carrying out a full blood test and might possibly draw the wrong conclusions about the patient's state of health. The same thing happens if you only measure partial discharges, which many network operators do. So you do indeed detect partial discharges on the joints or cable accessories or possible electrical trees in the plastic insulation where discharges occur. This helps you to trace active faults in cables and cable accessories that could lead to failure in the foreseeable future. However, you learn little about the overall condition of the cable insulation and the influence of moisture, which is why dissipation factor measurement is important. You will obtain the fullest information by interpreting the results of both methods together.

Why is it better to evaluate the results of partial discharge and dissipation factor measurements in combination?

Let me use an example to illustrate. If you carry out a partial discharge measurement and detect high partial discharges on a joint, for example, you are not yet able to interpret them properly because the partial discharges could be due to moisture. Dissipation factor measurement, on the other hand, indicates whether the cable accessories are dry. It is only when you know that the cable accessory is dry that you can correctly interpret the partial discharges measured on it and – if necessary – take appropriate action. Cable accessories affected by moisture must be interpreted differently compared to dry cable accessories.

Speaking of interpretation, many potential operators are troubled by the fact that there are no simple limit values, no "good" and "bad" in diagnostics. Why is that and how do you help operators?

Some people may think that evaluation is like reading tea leaves. But that's not the case. What we lack are fixed limit values for PD measurement and values that can be applied to all types of cables or to mixed routes. That makes things more complex.

We therefore help operators to interpret their measurement results and, if requested, can develop an evaluation strategy and assessment logic with them, as well as helping with evaluations. The assessment logic is customised and can therefore differ from network to network, depending also on the properties. However, our own experience is also part of the process. It is therefore possible to provide start-up assistance based on a great deal of practical experience.

Repeat measurements, trend analyses, root cause analysis of failed cable routes, and much more besides create a wealth of experience for the operator, which makes cable diagnostics more valuable for the company year on year, as well as resulting in slight modifications to the assessment logic.

The evaluation logic allows derivation of specific action plans. With the home of diagnostics and our Centre of Excellence, we support operators on this path. Long-term relationships with customers help to expand their wealth of experience and also to expand our expertise and share it with other customers. After all, it was a close customer relationship that resulted in one of our software solutions, which enables operators to convert the values from dissipation factor measurement into an ageing index and calculate the remaining life time, namely statex®.

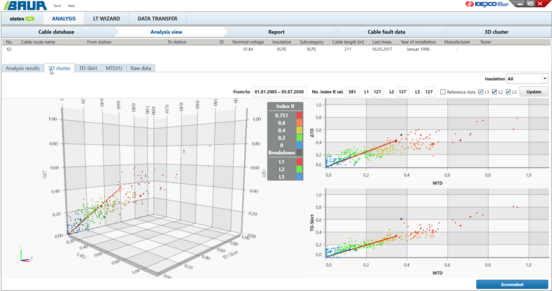

Ah yes, the statex® analysis software for calculating service life. What exactly does it do?

The statex® software is based on an evaluation logic created by Korean company KEPCO for its analyses of dissipation factor measurement.

Together with BAUR, this resulted in statex®, a solution that incorporates statistical calculation methods and a great deal of experience. Hence the name, which is composed of "statistics" and "experience". The software uses a database in which the measured values of more than 120,000 cables are stored. Initially, only the values of XLPE cables were stored here, but the diagnostics results of PILC cables and mixed routes are now also included.

Operators who use statex® can therefore very reliably determine the remaining life time of their cables, based on the entire database.

And the result obtained from statex® is the remaining life time in years?

Yes, but not only that. On the one hand, the software determines the expected remaining life time. And this calculation is validated even more precisely by subsequent repeat measurements, which take into account the ageing of each individual cable. On the other hand, statex® makes recommendations as to when it makes sense to repeat dissipation factor measurement or whether medium- or short-term upgrade measures need to be planned. This means that operators do not need to carry out diagnostics at fixed intervals, but can plan diagnostics based on the condition. Good cables are measured again after a longer period of time than those that are at the end of their service life. Demand-orientated diagnostics planning generally frees up work capacity so that more cables in the network can be diagnosed. This in turn increases savings and reliability.

Finally, Mr Neier, could you share some advice for those who are just starting out with cable diagnostics?

Of course. I would advise newcomers to take advantage of our advice and support and thus benefit from over thirty years of experience in the field of VLF cable diagnostics. With an evaluation logic, clear actions can be derived right from the start. New customers can rely on our extensive experience and achieve added value from the very beginning. This avoids bad investments and helps to implement a targeted diagnostics strategy. The time you invest pays off. Ultimately, users of cable diagnostics can save considerable sums without jeopardising the reliability of the network – and asset management has the basis for network maintenance planning.

Further information